Welder Resume Examples & Professional Resume Guide for 2025

- 30% higher chance of getting a job‡

- 42% higher response rate from recruiters‡

Our customers have been hired at:*Foot Note

Welders are skilled professionals who combine metal pieces through welding. They use specialized equipment and techniques to melt and fuse metal materials, creating solid and durable bonds. Welders work in various industries, including construction, manufacturing and automotive, to name a few. They are responsible for reading and interpreting blueprints and plans, selecting the appropriate welding method and materials, and ensuring the quality and integrity of the welds. Welders require extensive training and experience to master their craft, making them highly sought-after professionals in the job market.

A great job as a welder demands an impactful welder resume. Our guide and welder resume examples will show you how to write an effective resume to get the welder job of your dreams.

Start by editing this welder resume sample, or explore our library of customizable resume templates to find a suitable welder resume template.

Welder resume example (text version)

Erica Carter

Charlotte, NC 28210

(555) 555-5555

example@example.com

Professional Summary

Dedicated and skilled welder with experience in metal fabrication and welding. Proven expertise in interpreting blueprints, executing precise welding techniques and ensuring the highest quality in the finished product. Adept at working in diverse environments and committed to safety, efficiency and continuous improvement.

Skills

- Welding techniques (MIG, TIG, Stick)

- Blueprint reading and interpretation

- Quality control

- Metal fabrication

- Safety compliance

- Teamwork

- Communication

- Time management

Work History

November 2022 – Current

Accel Welding and Fabrication – Charlotte, NC

Welder

- Implement MIG and TIG welding techniques to fabricate high-precision metal components, resulting in a 20% reduction in production time.

- Execute over 20 welding projects for clients, achieving a 98% customer satisfaction rate based on project quality and timely delivery.

- Collaborate with the engineering team to identify and resolve welding defects, reducing rework by 15% and ensuring seamless production flow.

September 2019 – October 2022

FC Contractors Inc. – Charlotte, NC

Construction Welder

- Executed precise welding on structural components, including beams and columns, based on engineering blueprints.

- Contributed to a 15% reduction in project completion time by executing on-site welding tasks efficiently and maintaining high welding quality standards.

- Managed welding consumables and materials to minimize waste and control project costs, resulting in a 20% reduction in welding consumable expenses, contributing to project cost savings.

June 2015 – August 2019

American Welding Services – Charlotte, NC

Welder Assistant

- Supported senior welders in implementing materials for welding, including cutting, grinding and cleaning surfaces.

- Assisted in the maintenance of welding equipment, resulting in a 15% decrease in unexpected breakdowns and increased overall equipment lifespan.

- Followed and promoted adherence to safety protocols and guidelines during welding activities, contributing to a 20% decrease in safety incidents and fostering a safer working environment for the entire team.

Education

Central Piedmont Community College Charlotte, NC

Associate of Applied Science Welding Technology

Certifications

AWS Certified Welder – (Updated 2024)

OSHA 30-Hour Construction Safety Certification – (2023)

5 essentials of a top resume for a welder

Contact details

As our welder resume example shows, our contact information belongs in the header of your welder resume template. Include your full name, city, state, ZIP code, phone number and professional email address. Add your LinkedIn profile and a professional website if you have them.

Professional summary

A professional summary is a brief statement that introduces you to the hiring manager and tells them what you offer. A strong welder resume summary displays a few job-relevant skills and tells hiring managers why you are the best match for the job. If you are just starting your career, writing a welder resume objective is better.

Here’s an example of a great welder resume summary:

“Highly skilled and experienced welder with 10 years of experience in the industry. Proficient in various welding techniques, including MIG, TIG and stick welding. Proven track record of producing high-quality welds and meeting project deadlines. Strong knowledge of welding safety protocols and working efficiently in team and individual settings.”

Skills

Every resume must have a skills section so hiring managers can see what you bring to the table at a glance. Add a mix of skills in your welder resume skills section so hiring managers can see that you are well-rounded and able to perform the necessary duties of the position.

For example, welders must understand safety protocols and procedures to protect themselves and others from potential hazards. In addition, welding involves working with small tools and intricate parts, so welders need to have good fine motor skills and manual dexterity.

Work history

Display your current and past achievements in your welder resume job history section. From the most recent job, display your current and previous employers and provide company names, locations and the dates you worked for them. Emphasize your accomplishments in three to five bullet points for each job.

For example:

- Increased welding production by 20% through implementing efficient welding techniques and reducing material waste.

- Completed 500+ welding projects with a 98% satisfaction rate from clients.

- Trained and mentored 10 new welders, resulting in a 25% increase in overall team productivity.

Education:

An education section is necessary for every resume. If you are just starting as a welder, use the functional resume format and place your education section at the top. However, if you have some experience, including your education at the bottom of your resume is better. Start from the most recent school and work your way down. Display the years you attended, what you studied and the degrees you earned (if any). Also, highlight awards or high grade point averages.

You typically need a high school diploma or equivalent to become a welder. However, many employers prefer to hire candidates who have completed a formal training program, such as a vocational or technical school, community college, or trade school. These programs often include courses in blueprint reading, mathematics, welding theory and hands-on training in various welding techniques.

See why MyPerfectResume is a 5-star resume builder

Action words for a standout welder resume

Use action words and numbers to make your descriptions compelling.

Here’s a short list of perfect action words for a welder resume:

- Fabricate

- Join

- Weld

- Cut

- Repair

- Inspect

- Assemble

- Grind

- Solder

- Maintain

Ready to create your best welder resume? Our Resume Builder has all the tools you need to create a professional resume in minutes!

Top skills for a welder resume

Review the job description closely and match the required skills to the ones that fit you.

Some technical and soft skills for a welder resume might include:

- Knowledge of welding techniques and processes.

- Familiarity with different types of metals and materials.

- Ability to read and interpret blueprints and technical drawings.

- Knowledge of welding safety procedures and equipment.

- Dexterity and physical stamina.

- Communication.

- Attention to detail.

- Time management.

- Problem solving.

- Adaptability.

Review our library of resume examples for more inspiration.

Certifications for a welder resume

Welders must undergo training and pass a certification exam to demonstrate their proficiency in various welding techniques and safety practices. Many employers require their welders to hold specific certifications in industry standards and regulations. Research the particular certifications required in your area and pursue them to increase your job opportunities and earning potential.

Some certifications available to welders include

- Certified Welder (CW): Offered by the American Welding Society (AWS), this certification is the most widely recognized and accepted in the welding industry.

- Certified Welding Inspector (CWI): Also offered by AWS, this certification is for those who inspect and oversee welding operations.

- Certified Welding Educator (CWE): This certification is for educators who teach welding techniques and processes.

- Certified Welding Supervisor (CWS): Offered by AWS, this certification is for welding supervisors who oversee and manage welding operations.

- Certified Welding Engineer (CWE): This certification is for engineers who design and develop welding procedures and techniques.

- Certified Robotic Arc Welding (CRAW): Offered by AWS, this certification is for welders who specialize in robotic arc welding processes.

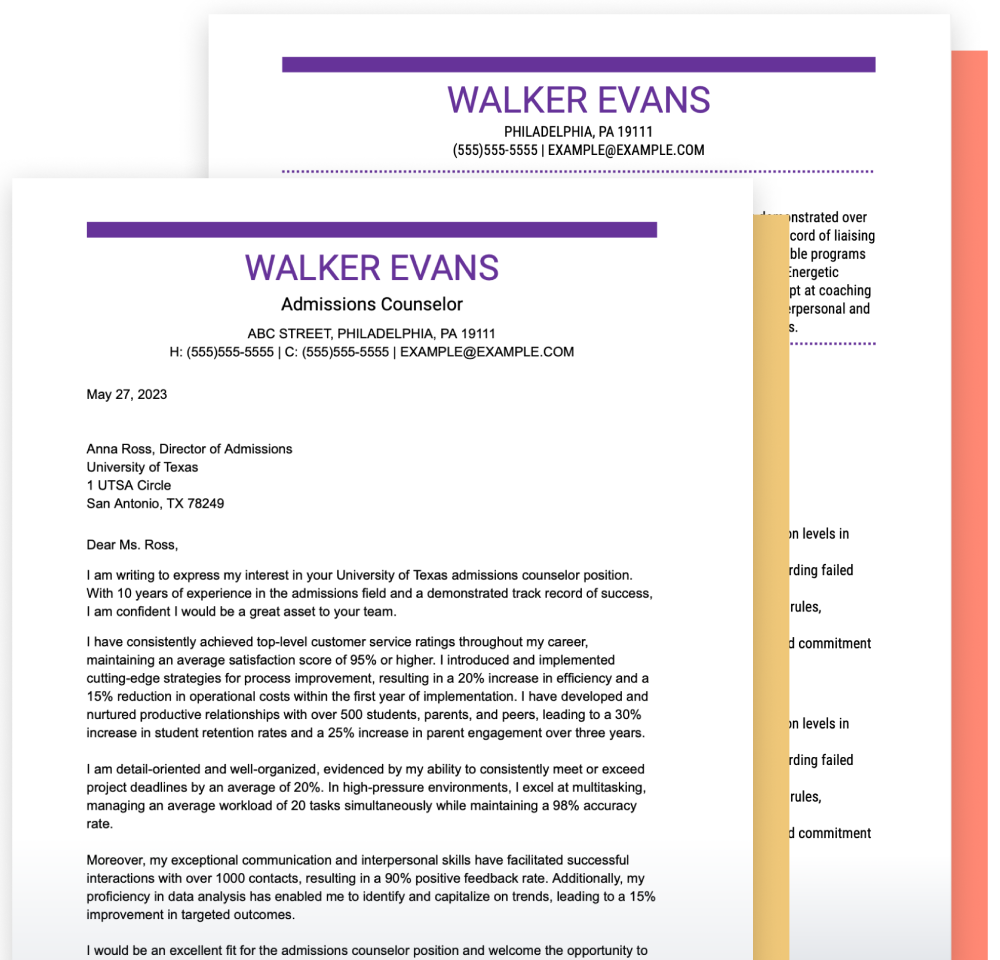

Pair your resume with a matching cover letter

Welder resume FAQ

What are some tips for making my welder resume stand out to potential employers?

Once you have the basics down, there are a few tricks to make your resume for a welder job stand out.

- Include specific projects and accomplishments. Instead of just listing your job duties, showcase specific projects or accomplishments you are proud of. Doing so will demonstrate your welding skills and experience in a practical way.

- Quantify your achievements. Whenever possible, include numbers or statistics to quantify your achievements. For example, if you improved welding efficiency by a certain percentage, include that in your resume.

- Use industry-specific keywords. Many employers use applicant tracking systems (ATS) to scan resumes for specific keywords. Include relevant industry-specific keywords in your resume to increase your chances of being selected.

- Highlight any additional certifications or training: If you have any additional certifications or training related to welding, including them in your resume will show potential employers that you are dedicated to your craft and constantly seeking to improve your skills.

- Customize your resume for each job. Tailor your resume to the job you are applying for to show potential employers that you have taken the time to understand their company and the role you are applying for.

- Showcase your attention to detail. Welding requires a high level of precision and attention to detail. Make sure your resume reflects these qualities by proofreading for any spelling or grammatical errors.

- Create a section for awards and recognition. A separate section for awards and recognition in your field is another way to emphasize your work achievements. It shows that you have gone above and beyond in your previous roles and have been recognized for your efforts.

What is the best resume format for a welder?

The resume format you choose for your welder resume will depend on your experience and career goals. The most common format is the chronological resume. It is popular among job seekers with at least one year of consistent work experience.

What if I have no previous professional experience as a welder?

When writing a welder resume with no experience, highlight your skills and potential rather than your lack of experience. Start with a functional resume template by creating a skills section with categories for technical skills or knowledge, such as knowledge of welding techniques and the ability to read blueprints, and a category for transferable skills that are essential in the welding industry, such as teamwork, time management and attention to detail.

Next, include any relevant coursework or training you have completed, such as welding safety courses or welding technology classes. Even if you have not worked in a welding-related job before, you can still include any relevant work experience, such as construction or mechanical work, that showcases your ability to work with tools and machinery.

Do’s and don’ts for building a welder resume

- Use measurable achievements like “Reduced material waste by 25% by implementing a more precise welding process.”

- Use action words like repair, join and operate to impact your welder resume.

- Tailor your resume to your target welder job.

- Use keywords from the job description throughout your welder resume.

- Format your welder resume so that it is easy to read by ATS software and human eyes.

- Lie about your welder experience and skills.

- Boast about your achievements. Instead, display your awards, like “Winner of the National Welding Supply Association’s Welding Excellence Award, 2022.”

- Include irrelevant personal information such as your ethnicity and age.

- Add skills and experience that are about something other than welding.

- Forget to proofread! Failure to proofread could be the factor that costs you the job.

Top 4 tips for acing a welder interview

Research first.

It’s vital to take the time to learn about the institution or company’s history, goals, values and people. Doing so conveys interest, passion and commitment — traits that can set you above the competition.

Some things to consider:

- Company reputation. Research the company’s reputation in the industry. Look for reviews or ask for recommendations from other welders who have worked with the company before.

- Work environment. Consider the work environment and safety protocols in place. Is the workplace well-organized and safe? Are proper safety equipment and procedures being followed?

- Equipment and technology. Look into the type of equipment and technology used in the company. Is it up to date and in good condition? This can significantly impact the quality of your work and safety.

- Company culture. Consider the company culture and values. Is it a good fit for you? Do they have a positive and inclusive work environment?

- Opportunities for specialization. Some companies may offer opportunities for welders to specialize in a specific type of welding. Research if the company provides such opportunities if you have a particular interest or skill.

Practice your answers.

Practice is critical. Practice for your interview by reviewing the most common interview questions.

For example, “Explain how you juggle multiple deadlines” and possible behavioral questions such as, “Describe a time when you put our needs aside to help a colleague.”

And, of course, prepare answers for possible welder-specific questions, such as:

- What type of welding certifications do you have?

- Have you worked with different materials like stainless steel, aluminum and titanium?

- How many years of experience do you have as a welder?

- Can you read and interpret welding blueprints and diagrams?

- How do you ensure you follow safety measures while welding?

- Have you worked with welding techniques such as MIG, TIG, or stick welding?

- Tell me about a time when you encountered a difficult welding project and how you handled it.

- How do you stay updated on the latest welding techniques and equipment?

- Can you work with a team and follow instructions from a lead welder?

- Have you ever encountered a problem with a weld and how did you troubleshoot it?

Write down two or three possible answers for each question, then practice answering them with a friend.

Prepare questions to ask during the interview.

After the hiring manager and potential colleagues question you, they will likely offer for you to ask some questions. Always have at least three for each person you speak with; doing so shows that you’re interested and have been paying close attention.

Some questions you might ask for a welder job:

- What materials will I be working with?

- Are there any specific welding codes or certifications I need to have?

- What safety measures are in place for welding on site?

- What is the work schedule like? Are there any overtime or weekend work requirements?

- Are there opportunities for advancement or further training?

- Can you tell me about the welding equipment and tools used in this company?

- How do you handle and prioritize welding projects?

- What is the company’s approach to quality control and meeting welding standards?

- Can you provide information about the company’s welding procedures and protocols?

- How does the company handle any welding-related accidents or injuries?

Gather references

Have professional references ready during your interview in case the hiring manager offers you the job on the spot (yes, it happens!). Make a list of two or three former colleagues and a former manager willing to speak highly about your abilities to perform the welder job.

How we reviewed this article

Since 2012, we have helped more than 11 million job seekers. We want to make your career journey accessible and manageable through our services and Career Center’s how-to guides and tips. In our commitment to bring you a transparent process, we present our Editorial Process.

Sources

- American Welding Society. Certified Welder Program

- New England Institute of Technology. Blog. How to Get Into Welding

- U.S. Bureau of Labor Statistics. Occupational Outlook Handbook. Welders, Cutters, Solderers, and Brazers

- Philadelphia Technician Training Institute. Article. What Qualifications do I need to Become a Welder?