Table of Contents

Get started with MyPerfectResume today!

- Build a resume on any device

- Pick an ATS-friendly template

- Tailor with AI copy suggestions

Why this resume works

- Quantifies accomplishments: Highlighting quantifiable achievements like reducing project costs by 15% and increasing client satisfaction by 25% showcases the applicant’s impact.

- Illustrates problem-solving ability: Successfully coordinating a team of 30+ construction staff and delivering projects ahead of schedule exemplifies their problem-solving skills.

- Uses action-oriented language: Action verbs like “supervised,” “managed,” and “coordinated” emphasize the applicant’s initiative in achieving goals.

More Construction Superintendent Resume Examples

Explore our construction superintendent resume examples to learn how to highlight your leadership, project management skills, and field experience for a compelling resume that lands you interviews.

Entry-level construction superintendent

Why this resume works

- Puts skills at the forefront: By placing skills like project management and safety compliance at the top, this applicant showcases the necessary skills for an entry-level role.

- Sections are well-organized: Effective use of bullet points and headers makes the resume easy to scan, ensuring key achievements are quickly accessible and improving readability.

- Effective use of keywords: By incorporating keywords such as “managed project budgets” and “optimizing project efficiencies,” the applicant ensures their resume passes ATS filters.

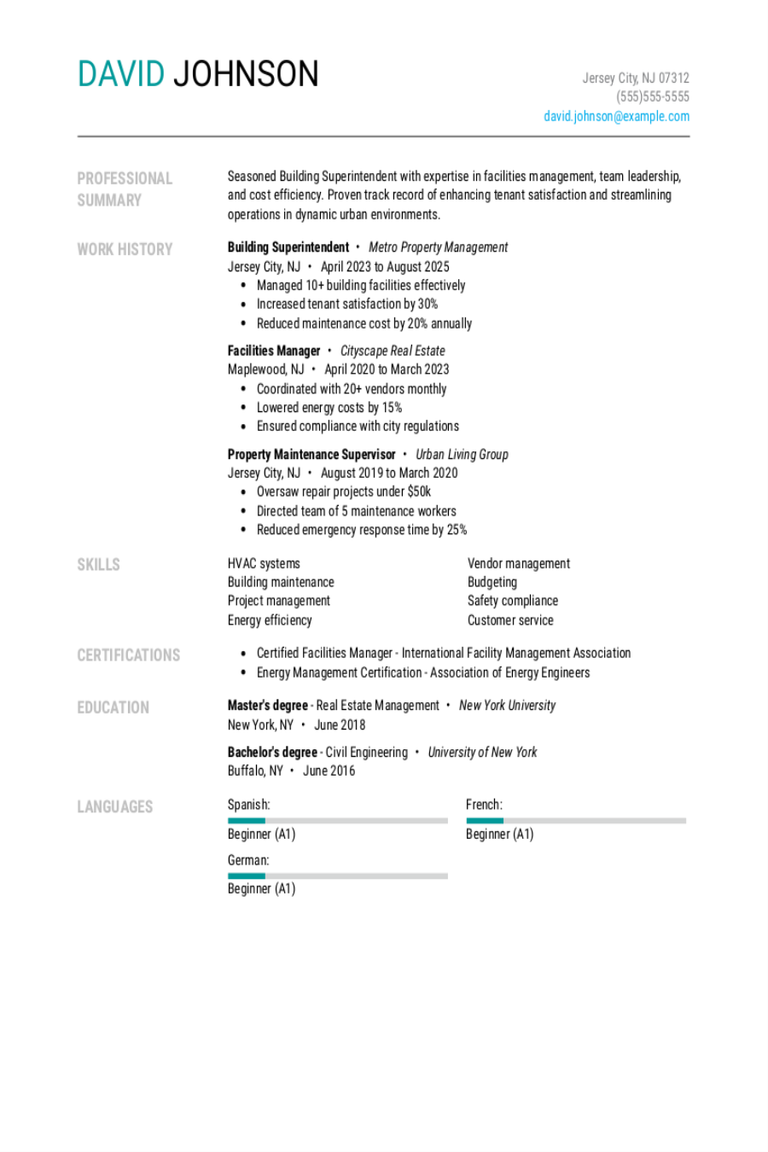

Mid-level construction superintendent

Why this resume works

- Points to measurable outcomes: By achieving measurable outcomes like reducing budgets by 15% and completing projects 30% faster, the applicant effectively showcases a results-driven mindset that benefits both teams and stakeholders.

- Includes a mix of soft and hard skills: Combining technical expertise in budgeting and safety protocols with interpersonal skills such as team leadership, the applicant presents a balanced approach to managing complex construction projects efficiently.

- Demonstrates language abilities: Including language skills in Spanish and German alongside basic French highlights the applicant’s ability to support cross-cultural collaboration, important for diverse project environments.

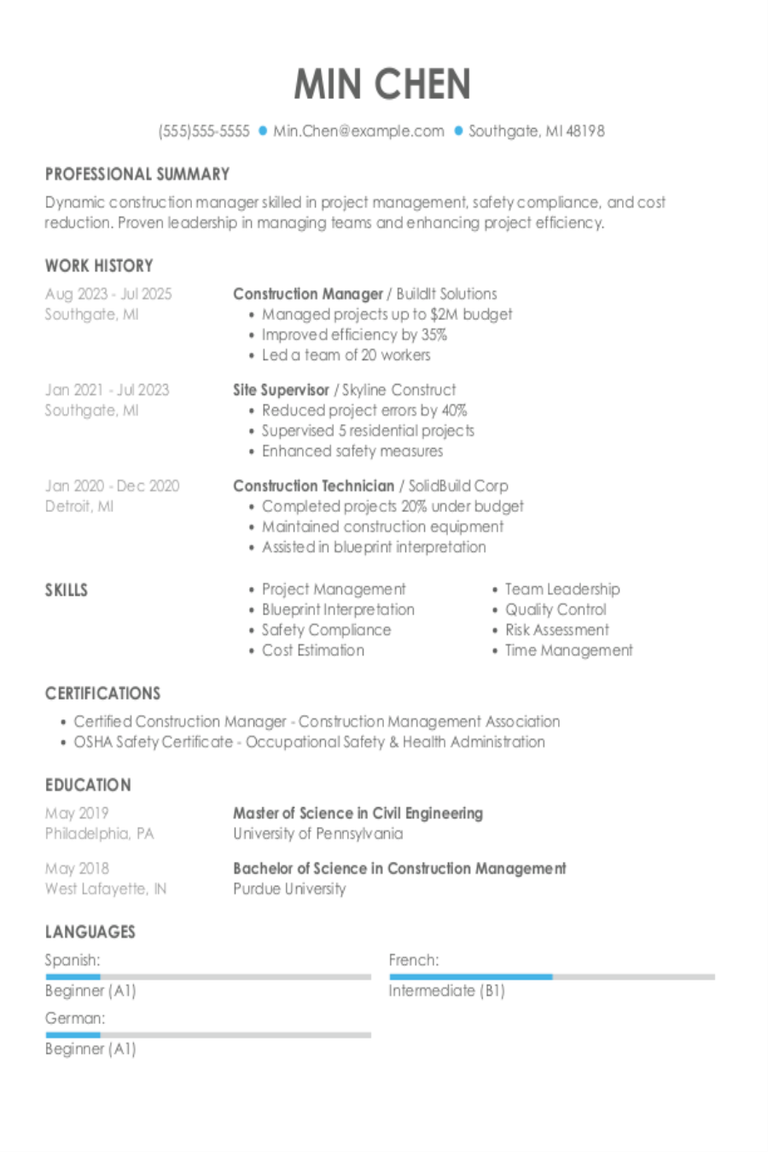

Experienced construction superintendent

Why this resume works

- Showcases impressive accomplishments: By detailing achievements like reducing waste by 20% and optimizing procurement, the applicant’s accomplishments reveal a knack for impactful strategic planning.

- Lists relevant certifications: Listing relevant certifications such as Certified Construction Manager and LEED Green Associate emphasizes dedication to industry standards and continual growth.

- Emphasizes leadership skills: The applicant’s history of leading projects with 95% on-time completion effectively showcases their leadership skills in managing complex tasks efficiently.

Construction Superintendent Resume Template (Text Version)

John Zhang

St. Louis, MO 63105

(555)555-5555

John.Zhang@example.com

Professional Summary

Dynamic construction superintendent with over seven years of experience managing complex projects, ensuring safety compliance, and leading diverse teams. Proven track record of reducing costs and increasing client satisfaction using strategic solutions and technical expertise.

Work History

Construction Superintendent

Premier Construction Solutions – St. Louis, MO

January 2022 – June 2025

- Supervised projects exceeding M budget

- Managed 15% cost reduction in materials

- Coordinated a team of 30+ construction staff

Project Manager

Skyline Builders Inc. – St. Louis, MO

June 2019 – December 2021

- Delivered projects 20% ahead of schedule

- Led 10+ cross-functional teams

- Boosted client satisfaction scores by 25%

Site Supervisor

Texan Developments LLC – St. Louis, MO

June 2017 – May 2019

- Oversaw safety compliance on M site

- Achieved 100% on-time completion rates

- Trained 20+ junior staff on site protocols

Skills

- Project Scheduling

- Budget Management

- Safety Compliance

- Leadership

- Team Coordination

- Quality Assurance

- Risk Management

- Blueprint Interpretation

Certifications

- PMP Certification – Project Management Institute

- OHSA Safety Certification – Occupational Safety and Health Administration

Education

Master of Science Construction Management

University of Texas Austin, Texas

June 2016

Bachelor of Science Civil Engineering

Texas A&M University College Station, Texas

June 2014

Languages

- Spanish – Beginner (A1)

- French – Beginner (A1)

- Portuguese – Beginner (A1)

Related Resume Guides

Advice for Writing Your Construction Superintendent Resume

Discover our tailored tips on how to write a resume for a construction superintendent role and learn how to highlight your leadership in managing projects, coordinating teams, and ensuring safety standards. Whether you’re just starting out or seeking new opportunities in the field, these insights will help you stand out in the construction industry.

Highlight relevant technical skills

For a construction superintendent, technical skills are key to managing projects smoothly. These skills help in planning, organizing, and overseeing building sites. It’s helpful to have a “Technical Skills” section on your resume to give employers a quick view of what you can do. Be sure to list any specific tools or systems you’re familiar with, such as AutoCAD or project management software.

If you’d rather include your technical skills in the work experience part of your resume, make sure they’re easy to spot. Describe how you’ve used these skills in past jobs. For example, mention how you led teams using scheduling software or managed safety protocols effectively on-site.

Common technical skills for this role include:

- Knowledge of building codes and regulations

- Understanding of construction methods and materials

- Skill in scheduling and budgeting software

- Ability to read and interpret blueprints

Highlighting these will show that you’re ready to handle the complex tasks that come with being a construction superintendent.

Example of a technical skills section

- Project management software (Procore, Buildertrend)

- Construction scheduling (Primavera P6, MS Project)

- Building codes and regulations compliance

- Quality control and assurance

- Site safety management

- Budgeting and cost estimation

- Blueprint reading and interpretation

- Subcontractor coordination

- Resource allocation and logistics planning

- Construction documentation and reporting

Your resume should show also how you use soft skills like teamwork, communication, and leadership to succeed at work.

Quantify your accomplishments

Quantifying accomplishments on a resume makes your experience as a construction superintendent much more engaging than just listing job duties. When you add numbers, like percentages or cost savings, it shows exactly what you achieved in each project.

In the work experience section, including measurable results alongside your job title, employer name, location, and employment dates helps tell a complete story of your impact. Instead of saying “managed construction projects,” you could say “managed construction projects that reduced costs by 15%.” This clearly shows what you did and how well you did it.

Using action verbs with metrics creates a powerful picture of your skills and achievements. Words like “supervised,” “implemented,” or “optimized” paired with specific outcomes make your resume results-driven rather than duty-focused. For example, highlighting time savings or efficiency improvements gives hiring managers quick insight into your problem-solving abilities.

These detailed entries help hiring managers quickly assess your skill set and influence within the construction field. By turning duties into achievements with clear, measurable results, you’re demonstrating not only what you’ve done but also how effectively you’ve done it.

5 construction superintendent work history bullet point examples

- Managed construction projects valued at $10M+, consistently delivering on time and under budget by 15%.

- Supervised a team of 50+ workers, improving project efficiency by 25% through targeted training and development.

- Implemented safety protocols that resulted in a 40% reduction in workplace incidents over a 12-month period.

- Coordinated with subcontractors to streamline operations, reducing project delays by 20%.

- Led weekly progress meetings with stakeholders, improving communication and project alignment, achieving milestones ahead of schedule.

Looking at professional resume examples can give you ideas on how to make your own resume stand out.

Write a powerful professional summary

A professional summary and a resume objective serve as introductions to hiring managers, helping them quickly understand who you are and what you bring to the table. It’s important to choose between a professional summary or a resume objective because both serve different purposes.

A professional summary is typically three to four sentences that highlight your experience, skills, and achievements. It’s best for those with ample experience in their field. The purpose of a professional summary is to showcase your professional identity and value, giving employers insight into what you’ve accomplished so far.

In contrast, resume objectives are statements about your career goals. They’re ideal for entry-level job seekers, career changers, or those with employment gaps. While summaries focus on “what I’ve accomplished,” objectives emphasize “what I aim to contribute.”

Next, we will provide examples of both summaries and objectives tailored for various levels of experience, guiding you in crafting an effective introduction for roles like construction superintendent and others.

Construction superintendent resume summary examples

Entry-level

Recent graduate with a Bachelor of Science in Construction Management and OSHA 30-hour certification. Possesses foundational skills in project scheduling, site safety protocols, and blueprint reading. Eager to contribute to team success by supporting project managers and learning from seasoned construction professionals.

Mid-career

Construction superintendent with over seven years of experience in managing commercial building projects. Skilled in coordinating subcontractors, ensuring compliance with building codes, and maintaining project schedules. Known for effectively managing teams and delivering projects under budget while maintaining high-quality standards.

Experienced

Seasoned construction superintendent with over 15 years of experience leading large-scale residential and commercial developments. Expertise in strategic planning, resource allocation, and risk management. Proven track record of reducing project timelines by optimizing workflows and fostering strong relationships with clients and stakeholders.

Construction superintendent resume objective examples

Entry-level

Dedicated entry-level construction professional eager to leverage strong organizational and communication skills in a construction superintendent role. Committed to learning and growing within the construction industry by ensuring efficient project management and fostering collaborative team environments.

Career changer

Experienced logistics coordinator transitioning into construction supervision, bringing expertise in managing timelines, resources, and team coordination. Passionate about applying transferable skills to oversee construction projects effectively while maintaining high safety and quality standards.

Recent graduate

Ambitious recent civil engineering graduate seeking a construction superintendent position to apply academic knowledge in structural analysis and project management. Eager to contribute fresh perspectives to complex projects while developing hands-on experience in the construction field.

Choose a resume template with straightforward sections and readable fonts. Steer clear of complex designs or bright colors to ensure employers focus on your skills and experience without distraction.

Showcase your credentials

Listing certifications, licenses, and specialized training is important for a construction superintendent because it shows expertise in technical areas and compliance with industry standards. These credentials help employers see that you’re prepared to oversee complex projects safely and efficiently.

A dedicated certifications section makes it easy for hiring managers to find these qualifications quickly. Including this information alongside your education section can give a fuller picture of your professional background.

Some helpful certifications for construction superintendents, include:

- OSHA 30-Hour Construction Training

- Certified Construction Manager (CCM)

- Construction Health and Safety Technician (CHST)

- LEED Accredited Professional (AP)

- CPR and First Aid Certification

Adding industry-recognized certifications builds trust in your ability to manage construction teams, budgets, and safety protocols effectively.

Employers want reassurance that their projects will meet regulations and quality standards under your leadership. Highlighting this section prominently can make a strong impression.

Example of a certifications section

Certified Construction Manager (CCM)

Issued by: Construction Management Association of America (CMAA)

Expires 2025

OSHA 30-Hour Construction Safety and Health

Issued by: Occupational Safety and Health Administration (OSHA)

Issued 2022

LEED AP Building Design + Construction

Issued by: U.S. Green Building Council (USGBC)

Expires 2026

Certified Professional Constructor (CPC)

Issued by: American Institute of Constructors (AIC)

Issued 2021

CPR/First Aid Certification

Issued by: American Red Cross

Expires 2027

Include either the issue date or expiration date of each of your certifications and licenses to show that your credentials are current.

FAQ

Do I need to include a cover letter with my construction superintendent resume?

Yes, adding a cover letter to your construction superintendent resume can boost your application.

A cover letter lets you spotlight your leadership skills and experience in managing construction projects, as well as any unique achievements or challenges you’ve tackled in past roles.

For example, if a company specializes in commercial buildings and you’ve successfully supervised similar projects, it’s a great moment to highlight that alignment.

Think about using tools like our Cover Letter Generator to draft your cover letter, ensuring it complements your resume by focusing on details like safety management and team coordination.

Additionally, checking out some cover letter examples focused on construction can provide ideas on how best to present your background and qualifications effectively.

How long should a construction superintendent’s resume be?

For a construction superintendent, using a one-page resume is usually best if you have less than 10 years of experience. Focus on key skills like project management, budget oversight, and team leadership. If you have extensive experience or specialized certifications in large-scale projects, extending to a two-page resume can be appropriate.

Make sure every detail is relevant to the construction industry, highlighting recent accomplishments and roles that show your ability to manage complex projects efficiently. Tailor your resume to showcase your unique strengths and how they contribute to successful project outcomes.

For more insights on determining the right length for your career stage, explore our guide on how long a resume should be.

How do you write a construction superintendent resume with no experience?

If you’re just starting out, a construction superintendent resume should highlight your relevant skills, education, and any experience that fits the role.

- Highlight educational background: Start with your degree in construction management or a related field. Include coursework that is relevant to the role, such as project management or safety regulations.

- Showcase transferable skills: Any leadership roles or responsibilities from other jobs can be highlighted here. Skills like team coordination, problem-solving, and time management are important for a superintendent.

- Leverage internships or volunteer work: If you’ve participated in any construction-related internships or volunteered on projects, detail these experiences. Focus on what you learned and how you contributed to the projects.

- Emphasize certifications: List any certifications such as OSHA safety training or first aid courses that are relevant to construction work. These show commitment and readiness to follow industry standards.

Look into resources specifically tailored for writing a resume with no experience to get more insights and practical examples.

Rate this article

Construction Superintendent

Share this page

Additional Resources

Building Superintendent Resume Examples & Templates

Browse building superintendent resume examples to see how to highlight your maintenance skills and experience managing properties. You’ll learn tips for showcasing your problem-solving abilities and effectively communicating with tenants.Build

Construction Resume Examples & Templates

Explore construction resume examples and tips to learn how to showcase your projects and highlight your construction experience in a way that stands out to hiring managers.Build my resumeImport existing

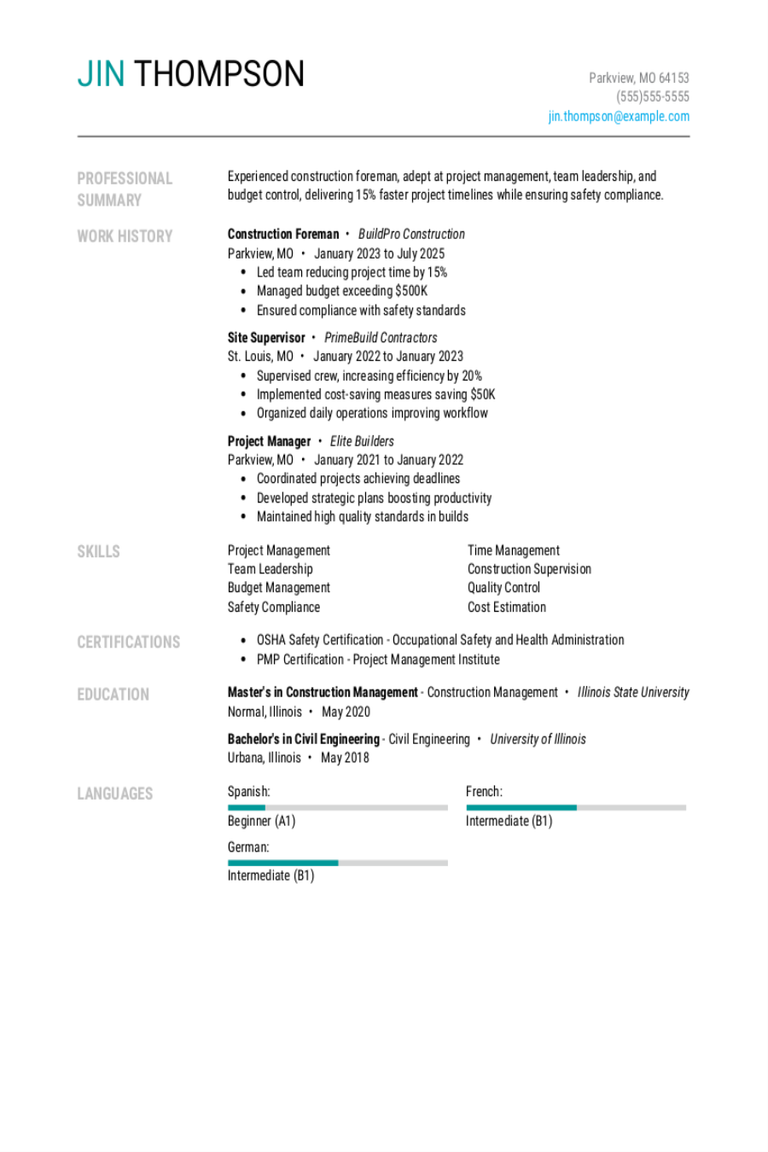

Construction Foreman Resume Examples & Templates

Explore construction foreman resume examples and tips to learn how show you effectively lead teams, keep projects on track, and ensure safety on site.Build my resumeImport existing resumeCustomize this templateWhy

School Superintendent Resume Examples & Templates

Explore superintendent resume examples that demonstrate strong educational leadership skills and effective management of district-wide operations. Use these tips to highlight your experience driving school improvement and advancing student achievement.Build

Assistant Superintendent Resume Examples & Templates

Explore assistant superintendent resume examples and tips to learn how to showcase your experience supporting school operations, managing staff, and ensuring academic programs run smoothly and meet district goals.Build my

Construction Worker Resume Examples & Templates

A construction worker resume should show how you build structures, use tools, and work safely. See our examples and tips for help making a resume that stands out.Build my resumeImport