Supply Chain Manager Resume Guide + Tips + Example

Our customers have been hired at:*Foot Note

Your logistics knowledge, relationship building skills and discerning analytical abilities set you apart. The right supply chain manager resume can help you advance your career. With our guide, you can create an effective supply chain manager resume to showcase you as the ideal candidate with the right skills and experience.

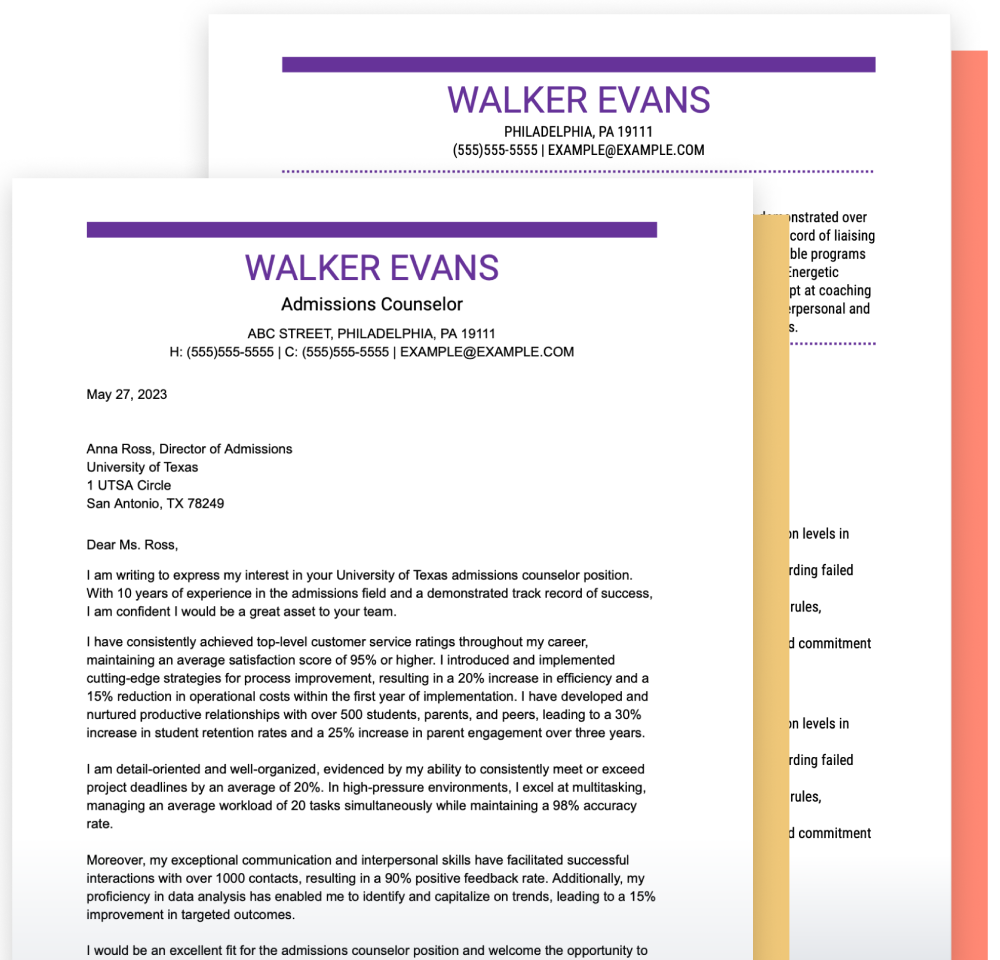

Start by editing this supply chain manager resume sample template or explore our good resume templates to find the best one for you.

Supply chain manager resume example (text version)

Dina Chase

San Acacia, NM 87831

(555) 555-5555

example@example.com

Professional Summary

Industrious supply chain manager skilled in leading and training staff members to achieve high performance. Talent in conducting performance evaluations and implementing continuous improvement strategies to promote organizational success. Excellent communicator with logistics coordination expertise.

Work History

February 2017 – Current

New Mexico Clay Inc – Lucan, NM

Supply Chain Manager

- Build supplier relationships to mitigate risk and establish effective purchasing arrangements with indirect and logistics customers.

- Devise and implement short-term and long-term plans, optimizing supply chain management and improving value relating to annual expenditures.

- Optimize supply chain infrastructure by assessing and initiating targeted changes to reduce operating costs by 15%.

May 2013 – February 2017

Acme United Corp – La Crescent, NM

Supply Chain Supervisor

- Oversaw supply chain and supported tech transfer projects, batch release testing, change management and resolution of customer complaints.

- Communicated directly with suppliers and analyzed contracts and service cost-effectiveness.

- Analyzed business operations to quickly resolve problems and manage workflow processes to keep projects on track, improving productivity by 30%.

June 2010 – April 2013

Lambda Mechanical – Keister, NM

Supply Chain Coordinator

- Improved 25% of quality assurance operations by inspecting materials and verifying delivery compliance.

- Gathered and analyzed supplier, inventory and distribution data to assess areas in need of improvement.

- Revised weekly production schedules to meet dynamic conditions such as supply shortages and backlogs.

Skills

- Supply chain distribution

- Negotiation

- Relationship building

- Vendor management

- Staff management

- Cost accounting

- Budget management

- International purchasing

Education

- New Mexico Highlands University Las Vegas, NM

- Bachelor of Science Logistics and Materials Management

Certifications

- Certified International Supply Chain Manager (CISCM) – (2019)

- ACSM Certified Supply Chain Professional (CSCP) – (2018)

5 essentials of a top supply chain manager resume

Contact details

Your supply chain manager resume will have all the information needed to reach you for an interview in the contact detail. Include your full name, city, state and ZIP code, followed by phone number and email address. Finally, add a professional website, LinkedIn profile or any other professional networking profile.

Personal statement

Also called a professional summary, this section in your supply chain manager resumeis your introduction to a potential employer. Here, you will showcase your best skills and relevant work experience to perform as a supply chain manager. In no more than five sentences, you will let the hiring manager know: your years of experience, one or two relevant professional accomplishments and your job-related skills. Pick your best to grab the hiring manager’s attention.

Skills

The skills section highlights your abilities to perform a job as a supply chain manager. Remember to match your skills to those on the job description. Create a bulleted list with hard skills, like inventory management, risk assessment and management, and demand forecasting, and soft skills like collaboration, analytical thinking and communication.

If this is your first job, include transferable skills from other employment.

Work history

The work history section of your supply chain manager resume shows your experience. Use a reverse-chronological order format to list your previous employment. Include the company names, locations and dates of employment, and for every job, include a bulleted list of three measurable accomplishments. For example:

- Improved stock accuracy by 10%, saving the company $50,000 annually

- Developed and implemented weekly forecasting models to optimize inventory allocation

- Coordinated international shipping activities for retail and wholesale customers.

If this is your first job, you can include other relevant work experience, like volunteer experiences, community services, professional projects and more.

Education

Use bullet points to create your supply chain manager resume’s education section. Include the educational institution’s name, the degree conferred and graduation year. You can skip the graduation date if it has been over 10 years.

If you did not attend college, list your high school and any other post-high school course you’ve completed.

See why MyPerfectResume is a 5-star resume builder

Action words for a stand-out supply chain manager resume

A resume is a one-page document that needs to leave a good impression. Using action words can help you add confidence and strengthen your achievements. Combine action words with your quantifiable accomplishments to make a great impression.

Here’s a short list of action words for a supply chain manager resume:

- Project

- Manage

- Analyze

- Implement

- Coordinate

- Prioritize

- Reduce

- Conduct

- Increase

- Streamline

Building a professional resume for a supply chain manager is quick and easy with our Resume Maker. It has all the tools you need, from editing to step-by-step guidance. Consider the expert suggestions and download the product once you’re satisfied with it. We have 400+ resume examples to help you create the perfect resume of a supply chain manager.

Top skills for a supply chain manager resume

The skills section should show balance between soft and hard skills. Carefully review the supply chain manager job description and match the required skills that fit you. This will help showcase you as a desirable candidate.

These are a few skills you could include in your resume of a supply chain manager:

- Supply chain operations

- Inventory management

- Manufacturing operations

- Market analysis

- Microsoft Dynamics 365

- Leadership

- Relationship building

- Risk management

- Report creation

- Customer service

- Informative Presentation

Certifications for supply chain manager resume

Certifications can add confidence to your knowledge and experience. By including certifications, your resume can stand out from other applicants.

These are a few certifications to consider for your supply chain manager resume:

- ACSM Certified Supply Chain Professional (CSCP)

- Certified International Supply Chain Manager (CISCM)

- Certified Logistics, Transportation and Distribution

- Certified in Production and Inventory Management (CPIM)

- ASCM Supply Chain Operations Reference (SCOR-P)

Pair your resume with a matching cover letter

Supply chain manager resume FAQ

What’s the right format for a supply chain manager resume?

The right format will depend on your years of experience. If you’re an experienced candidate, a chronological resume format will highlight your extensive experience and caree accomplishments. If you’re switching industries, a functional resume format will focus on your skills and downplay your lack of experience as a supply chain manager. If you have between three and nine years of experience, the combination resume format will balance the skills you have cultivated so far and the experience in the field.

Our Resume Builder can choose the right format for you by answering a few questions. Then, use our step-by-step guidance and expertly suggested content to complete your resume and download in your desired file format.

What should be the objective in a resume for a supply chain manager?

The section is called a personal statement or career summary. Write it as a sales pitch where you are the best product to offer or like an elevator pitch, where you have 30 seconds to attract interest in a product or service.

When deciding what to write, always keep the job description in mind and choose your most impressive accomplishments and skills relevant to the role. Prepare the personal statement as if it is the only section the hiring manager will read.

For example:

APICS certified supply chain manager with 15 years of experience. Focused on streamlined services to lead the production team in high performance. Advanced analytics user to improve logistics. Received President’s Award during tenure at Important Company.

How much does a supply chain manager make?

According to the Bureau of Labor Statistics, the median pay for a supply chain manager is $77,030. BLS also reported that the logistics industry has a projected growth rate of 28% during this decade. Logistics are used in different industries and it is a fast-paced environment.

Do’s and don’ts for building a supply chain manager resume

- Use measurable achievements to describe your abilities and experience as a supply chain manager.

- Use action words to make an impact on your supply chain manager resume.

- Tailor your resume to your target supply chain manager job.

- Use keywords from the job description throughout your supply chain manager resume.

- Format your supply chain manager resume so that it is easy to read by ATS software and human eyes.

- Lie about your supply chain manager experience and skills.

- Boast that you’re the “best supply chain manager ever.”

- Include irrelevant personal information, such as your ethnicity and age.

- Add skills and experience not pertaining to supply chain management.

- Forget to proofread. A supply chain manager resume with errors is unprofessional.

Top 4 tips for acing a supply chain manager interview

Research the prospective employer before your interview.

Learn about the employer’s history, goals, values and people before your supply chain manager interview. Showing in-depth knowledge about a potential employer highlights your interest, dedication and commitment — traits that make a desirable candidate.

Practice at home.

Start by reviewing the most common interview questions, such as:

- How Have You Motivated Others? Give Me an Example.

- What Has Your Experience Been Like With Public Speaking?

- What Was the Most Complex Assignment You Have Had and What Was Your Role?

- If There Were One Area You’ve Always Wanted to Improve Upon- What Would That Be?

Ask a trusted person, like a friend or relative, to perform a mock interview. Search for possible interview questions, write down the answers and then practice with your interview partner. Once you’re done, ask them for feedback and work with them to improve. Being prepared will help you have a smoother supply chain manager interview experience.

Pro tip: Practice in front of a mirror to work on your facial expressions and body language, which hiring managers will notice.

Be proactive and ask questions.

Prepare at least three questions prepared for the end of your interview. Hiring managers will expect questions as it shows your enthusiasm and interest in the role. Your questions can even improve their impression of you.

Here are a few examples of questions to get you started:

- Why did you choose to work for this company?

- What’s the biggest challenge the company has overcome?

- What tools do you provide for the success of all employees?

- How do you measure the success of your employees?

- How is performance measured?

- What improvements would you like to see in the near future?

Round up your references.

Contact former managers and colleagues to be potential references. They should be able to vouch for your work ethic and skills. Explain to them where you are in the process and when they could expect to be reached. Don’t forget to ask if they could write a letter of recommendation for you.

If this is your first full-time job, you can request a reference from a mentor, former professor, community leader, volunteer coordinator or classmate that can vouch for your skills.

Cover letter examples for the next step in your production career

How we reviewed this article

Since 2012, we have helped more than 11 million job seekers. We want to make your career journey accessible and manageable through our services and Career Center’s how-to guides and tips. In our commitment to bring you a transparent process, we present our Editorial Process.